Layers Egg Handling & Packing

Damtech Egg Handling

DamTech Egg Handling and Packing Systems represent the forefront of innovation in poultry processing, designed to optimize every stage of egg collection, sorting, and packing.

These state-of-the-art systems are engineered to deliver exceptional performance while ensuring the utmost care for your product.

With a focus on precision, efficiency, and quality, DamTech solutions cater to the evolving needs of modern poultry operations, from small farms to large commercial enterprises.

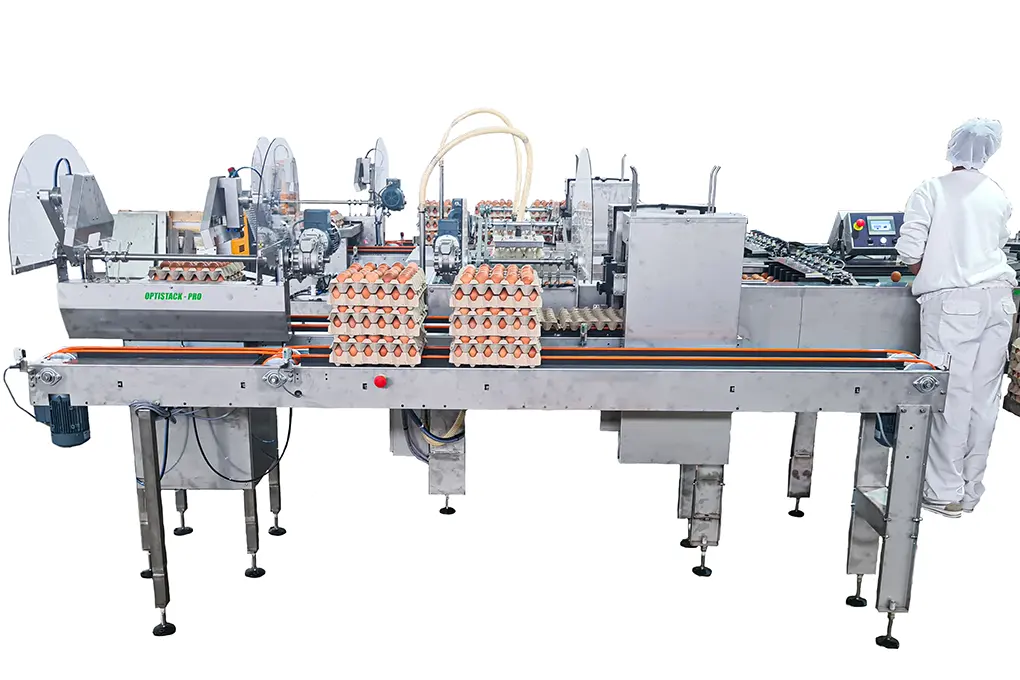

Egg Packing Systems

When selecting the right egg handling and packing system, several critical factors must be considered to ensure the best fit for your operation. Footprint is an important consideration; the system should align with the available space in your facility while allowing for smooth workflow and accessibility. Size and capacity are also crucial, as the system needs to match your production volume and future growth potential.

Additionally, consider the level of automation required, from basic manual systems to fully automated solutions that handle sorting, packing, and quality control with minimal human intervention.

Egg Palletizer

DamTech Egg Palletizing Systems offer an advanced solution for automating the final stages of egg processing.

Designed to handle high volumes efficiently, these systems ensure precise and consistent placement of eggs on pallets, minimizing damage and optimizing space utilization. The robust construction and high-capacity capabilities, DamTech’s Egg Palletizers are built to endure the demands of modern poultry operations. Their reliable performance enhances workflow efficiency and reduces labour costs.

Featuring user-friendly controls and customizable settings, these systems seamlessly integrate into existing processing lines, making them a smart investment for enhancing productivity and maintaining egg quality.

E-Grader 120 Detector

The E-Grader 120 Detector is a state-of-the-art contactless crack detection module that utilizes advanced vision technology, specifically designed for grading centres. This innovative system offers highly accurate crack detection, ensuring that you maintain complete control over your egg quality and safety. The system leverages sophisticated algorithms to analyse each egg in real-time, providing precise assessments without the need for physical contact. This not only minimizes the risk of further damage to the eggs but also enhances overall processing efficiency.

The E-Grader 120 is engineered to seamlessly integrate into existing grading lines, providing a user-friendly interface that allows operators to monitor detection rates and make informed decisions. Its ability to differentiate between minor cracks and more serious defects empowers producers to improve their quality control processes, ensuring only the highest quality eggs reach the market.

VDL Jansen FlexBelt

The VDL Jansen Flexbelt is meticulously designed to ensure that eggs produced with the utmost care are transported with the same level of precision and protection.

This advanced egg conveyor belt system maintains egg quality during transport through its uniquely shaped carriers and smooth egg transfers, effectively preventing shell cracks and preserving the integrity of each egg.

Its versatile design allows the Flexbelt to navigate left and right up to 180°, as well as adjust upwards by 35° and downwards by 30°, optimizing space utilization in both the house and collection room. This flexibility makes it adaptable to various spatial configurations and operational needs. The open construction of the belt facilitates easy cleaning, ensuring a hygienic environment for the eggs and simplifying maintenance tasks.

Additionally, the Flexbelt is compatible with all nest types and aviaries, with the capacity for indefinite expansion to accommodate growing operations. By integrating the VDL Jansen Flexbelt into your poultry system, you can enhance both efficiency and egg quality throughout your production process.